Advancing Connections

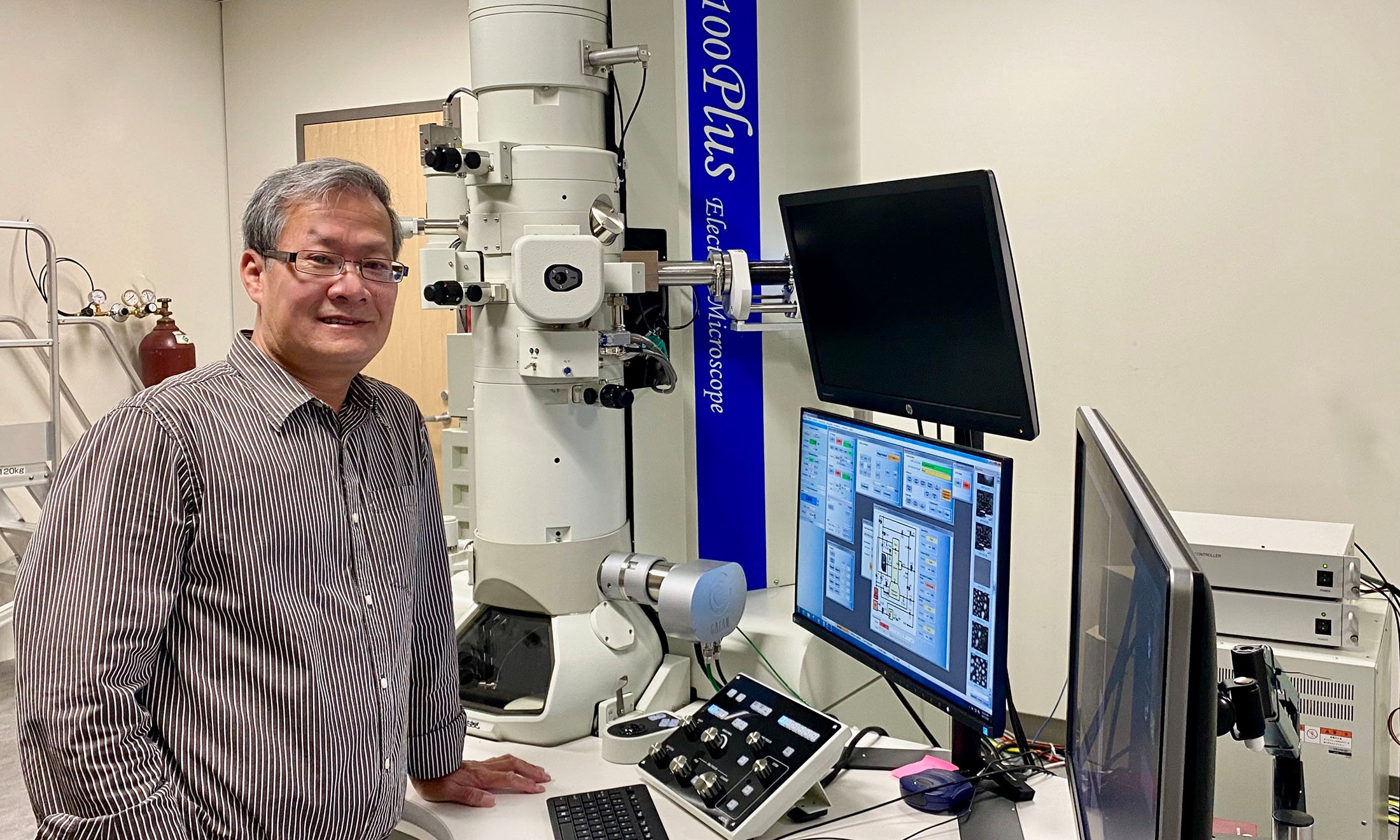

Hongwei Qu, Ph.D., professor of electrical and computer engineering, has been collaborating with Molex to improve electrical connectivity and reliability of electrical and electronic systems

To contribute knowledge and advance technology, SECS researchers partner with various industry-leading companies that push forward world-class manufacturing capabilities. Hongwei Qu, Ph.D., professor of electrical and computer engineering, has been collaborating with Molex, a highly regarded supplier of connectors and interconnect components, with the goal to improve electrical connectivity and reliability of electrical and electronic systems.

The joint project began at the end of 2018 and, after a successful year, was renewed in August 2020. “New connectivity devices and systems are very actively pursued by academia and industrial communities,” Dr. Qu says. “Our conveniently-located research facility as well as expertise in electrical and electronic materials and devices put us in a very favorable position for collaboration with Molex. While characterizations and knowledge of how to improve the materials systems belong to SECS, implementational methodology and intellectual property rights are owned by Molex.”

The research conducted within this collaboration targets applications where electrical/electronic connectivities and requirements are different from conventional systems, such as electrical vehicles. Electrical vehicles’ powertrains can experience a substantially higher electrical current density surge and have different working modes and environments for the control and power delivery circuits. As a result, performance, reliability and safety requirements become stricter.

To meet new challenges, Dr. Qu’s Microscopy and Microanalysis Laboratory conducts comprehensive materials studies, enabled by advanced instruments essential for micro- and nano-analysis of materials and devices. The lab features such state-of-the-art instruments as a Scanning Electron Microscope (SEM) with Energy Dispersive Spectroscopy (EDS), a Transmission Electron Microscope (TEM) with EDS, an X-ray Diffractometer (XRD) and a Nanoindentation System.

“The versatility of an SEM for morphological, structural and compositional analyses — when conveniently integrated with a spectroscopy such as EDS — has made it indispensable for our work. In addition to offering routine imaging resolution and focal depth, that are by far greater than an optical microscope, our JEOL JSM-6510/GS SEM allows for detailed measurements, including 3D measurements of microstructures of materials and devices,” Dr. Qu explains.

A TEM (JEOL JSM-2100 Plus) is the most recent addition to the laboratory, obtained from the National Science Foundation Major Research Instrumentation Program. It “sees through” material and reveals its crystal, polycrystalline and amorphous structures at an atomic level. Two other most frequently used tools are a Rigaku XRD, for powder and solid materials compositional and crystal structural analysis, and a NanoTest-600 nanoindenter for characterization of hardness and strength of solid materials in both thin-film and bulk forms.

“We characterize the materials using these advanced tools to provide necessary information on crystal grain structures on a micrometer (micron) scale for materials system optimization, which is crucial for targeted material property enhancement and overall system performance improvement. Our tools are essential to this type of research and one of the reasons why Molex partnered with our laboratory,” Dr. Qu adds.

Mr. Sherin Bhassyvasantha, a principle engineer at Molex, agrees, “It was a pleasant surprise to see many advanced instruments, critical for materials research, right here at OU. We didn’t realize that such a comprehensive research facility, which could substantially benefit Molex and other local companies, existed so close to us. SECS’s supportive environment was also a big plus. After we had evaluated the lab’s capability, we decided on a tentative project with Dr. Qu and his team — the work that has proved to be very successful.”

The project did receive financial support from Molex, in addition to other federal grants that Dr. Qu previously obtained for equipment sustainability. The researcher is pursuing long-term collaborations with Molex, as well as other companies, to apply his knowledge and to utilize his research facility for advanced research projects.

Learn more about Dr. Qu’s Microscopy and Microanalysis Laboratory.

December 10, 2020

December 10, 2020

By Arina Bokas

By Arina Bokas