The Front Runner

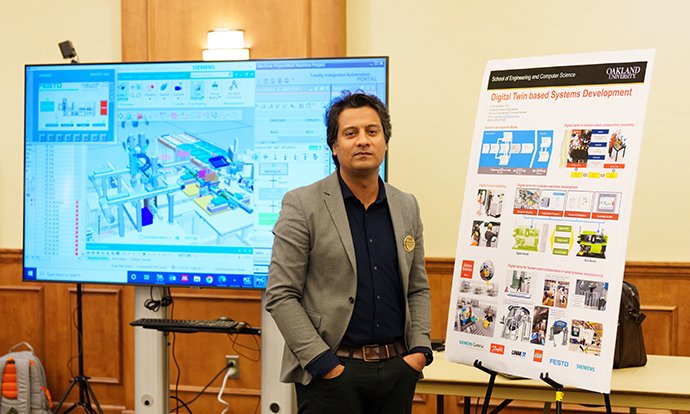

Dr. Ali Ahmad Malik explores usefulness of digital twins in designing, developing and operating production systems in the industrial setting.

Since the economy’s return to normal after the challenges posed by the pandemic, the buzzword “digital twin” (DT), challenging the very definition of what “normal” is, has been gaining traction in the manufacturing world. While companies are looking for solutions to remote operations, shorter product life cycles, mass personalization and interactions between humans and robots in close proximity, Ali Ahmad Malik, Ph.D., assistant professor of industrial and systems engineering, explores usefulness of digital twins in designing, developing and operating production systems in the industrial setting.

|

| Dr. Malik presents Digital Twin-based System Development at SECS Faculty Research Expo |

In the recent decade, the manufacturing ecosystem has been getting increasingly multifaceted, requiring highly complex biomechanical production plants with more adaptive, flexible and cost-effective operations. While, traditionally, human workers have been a flexible production resource, an ongoing increase in the cost of human labor dictates a new manufacturing paradigm, featuring human-robot collaboration (HRC). HRC can expand the level of automation in areas that have conventionally been difficult to automate.

“Automation exists to eliminate the need for humans to do repetitive, low-skilled work. It is not possible without human intelligence to engineer, oversee, control, and repair automation technologies. However, if the human [intelligence] and automation can be combined, creating a balance between the flexibility of manual processes and the efficiency and repeatability of machines, the advantages of production flexibility, product mix and reconfiguration can be significant,” Dr. Malik explains.

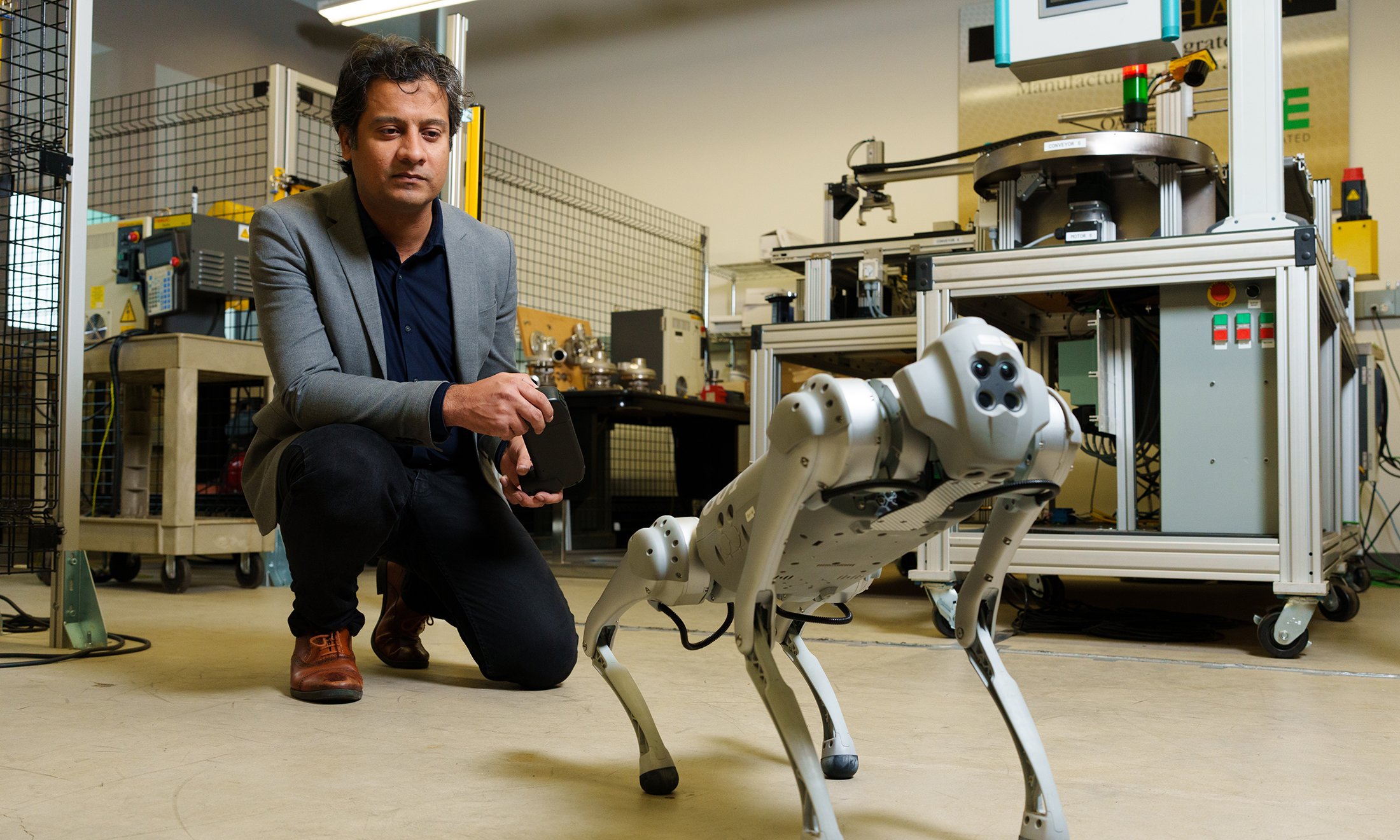

With the rise of Industry 4.0 technological trends, a growing tendency in manufacturing automation is human-friendly robots (i.e., cobots) designed for working alongside humans. Yet, as the level of collaboration increases, the systems become more complex, which limits the industrial application of cobots in labor-intensive processes. Thus, there is a need for exploring a digital twin’s potential to address the complexity of collaborative production systems.

“A digital twin is a virtual counterpart of a physical human-robot assembly system that is made as a ‘front runner’ for validation and control throughout its design, build and operation. As a digital representation of both the components and dynamics of a physical system, DT is enabled by the advancement in virtualization, sensing technologies and computing power,” Dr. Malik says.

Dr. Malik‘s study, focused on taking a holistic life cycle approach of digital twins for human-robot assembly systems, was originally conducted at a manufacturing facility in Denmark. The researcher composed a digital twin model for an HRC production system of two interconnected spaces — physical and digital. The digital space is a three-dimensional virtual representation of the co-existing human and robot, while the physical space is the real production system composed of humans, robots and other hardware. The usefulness of an HRC assembly system was assessed according to its potential to be agile, adaptable and safe for its human members.

The results of this study highlight a number of observations from design to operation of an HRC system.

In the design phase, the digital twin was used to design and select the resources of the assembly system corresponding to the production requirements and its relationship with the rest of the system. Dynamic simulation showed that the DT can continuously be evolved from manual data syncing to automated and real-time data syncing, thus enabling greater usefulness at the system level.

In the operational phase, the usefulness of DT has proven to be in the event-driven simulation; intuitive robot programming; human-safety assessments; generating data logs for critical actions by integration of sensors; and embedding artificial intelligence to get the system self-learned and make decisions according to its past experiences.

|

“The idea of a digital twin as a ‘front runner’ can lead the optimized behavior of a physical system by creating its time-dependent accurate virtual model and simulating it. With each change introduced in production parameters of the physical system, new variables are simulated to predict corresponding future behavior and highlight required optimizations. The behavior can be visualized and assessed without the risk of any financial loss or human injury that may otherwise be present in the real production,” Dr. Malik adds.

The research has been conducted at different manufacturing venues, such as LINAK and Siemens Gamesa. After joining Oakland University in January 2022, the researcher received a grant from Festo SE & Co. KG, a Germany-based global supplier of automation technology and technical education, to explore the usability of digital twins for system development in terms of reduction of development time, complexity and reconfiguration efforts.

Currently, Dr. Malik is involved as a co-principal investigator in ongoing work focused on digital twins in automotive cybersecurity. Additionally, he is forming a new project with LEGO, aimed at investigating artificial intelligence- based digital twins for intelligent manufacturing of the future.

Dr. Malik is open to new collaborations and offers research assistant opportunities to doctorate-seeking individuals. Anyone interested in participating and supporting his efforts can reach him at [email protected]

December 18, 2023

December 18, 2023

By Arina Bokas

By Arina Bokas